Stuck in port? The surprising lesson supply chains teach us about your customer queues

Customer queues are your silent bottleneck. Here’s what container ships and checkout lines have in common—and how to stop losing money to both.

Remember the images of cargo ships anchored offshore, empty store shelves, and businesses scrambling to get goods? The recent global supply chain crisis provided a stark reminder of what happens when flow meets friction.

While your business might not be managing container traffic, the same core dynamics are at play in your customer queues: too much input, not enough throughput. Whether it’s ships waiting to unload, patients waiting for a doctor, or customers in line at checkout, congestion is costly.

📝 This article was originally published on the QueueworX blog

The simple truth behind the logjam (and your queues)

When the rate of “arrivals” (whether it’s goods or people) exceeds your capacity to process them efficiently, bottlenecks form, and waiting times skyrocket.

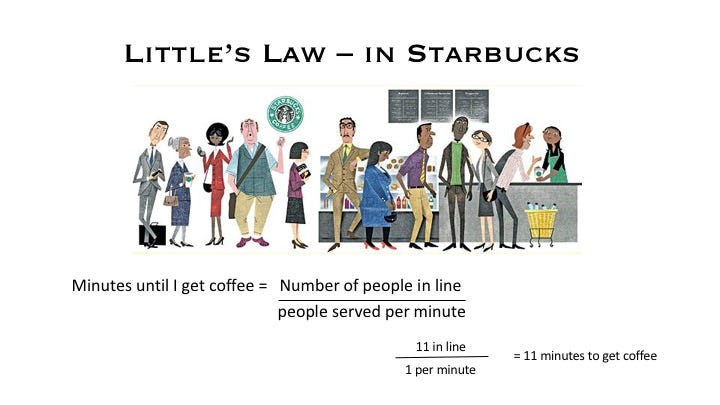

This isn’t just common sense—it’s math. A key insight from queueing theory, called Little’s Law, relates three essential elements:

Arrival rate,

Response time, and

The average number of items (or people) in the system.

When either arrival rate increases or processing slows down, your queue grows—guaranteed.

In simple terms, Little’s Law states that the average number of items in a system is equal to the average rate at which they arrive multiplied by the average time they spend in the system. Let’s break it down into practical terms:

More arrivals + same capacity = bigger queue and therefore longer waits

If the arrival rate of items (or people) increases while the system’s processing capacity remains the same, the average number of items in the system will increase. This leads to longer queues and longer wait times. For example, if a restaurant receives more customers than it can serve efficiently, the waiting area will fill up, and customers will have to wait longer to be seated and served.

Faster processing + same arrivals = smaller queue and shorter waits

Conversely, if the system can process items faster while the arrival rate remains the same, the average number of items in the system will decrease. This results in shorter queues and shorter wait times. For instance, if a call center improves its call handling efficiency, it can serve more customers in less time, reducing the number of people on hold and decreasing wait times.

The real-world implications

Port operations

Just like too many ships arriving at a port with limited unloading capacity leads to a backlog, a surge of customers arriving at your business without sufficient resources will inevitably lead to long wait times and frustrated customers. If a port can only unload a certain number of ships per day, an increase in the number of ships arriving will result in a queue of ships waiting to be unloaded.

Retail stores

During peak shopping hours, if a store does not have enough staff to serve customers efficiently, the checkout lines will grow longer, and customers will have to wait longer. Conversely, if the store increases the number of cashiers or improves the checkout process, the lines will become shorter, and customers will be served more quickly.

Healthcare facilities

In a hospital, if the number of patients arriving exceeds the capacity of the medical staff to treat them, patients will have to wait longer for their turn. By increasing the number of healthcare providers or optimizing the treatment process, the hospital can reduce wait times and improve patient satisfaction.

Understanding and applying Little’s Law can help businesses and organizations better manage their resources and improve customer satisfaction. By balancing the arrival rate with the processing capacity, they can minimize queues and wait times, leading to a more efficient and pleasant experience for everyone involved.

Beyond the fundamental relationship between arrival rate, processing time, and queue length, the structure of a queue also plays a significant role in optimizing customer flow.

Think about the different approaches businesses take to manage their lines. For example, many traditional grocery stores utilize multiple separate checkout lines, each with its own cashier (option A below). This is a common configuration of a multi-server queue, often driven by space constraints or the need for customers to manage their own items. However, this system can lead to frustration as customers perceive some lines moving much faster than others. In contrast, self-checkout systems or baggage drop-off counters at airports often employ a single, winding line that feeds into multiple available stations (option B below). This approach, also a form of a multi-server queue, aims to improve fairness and efficiency by ensuring that the next available server takes the next person in line.

These different methods, from multiple parallel lines to a single queue feeding many servers, represent different queueing disciplines. Each is a strategic choice aimed at optimizing flow and customer throughput – a balance that businesses across all sectors constantly strive to achieve.

The cost of “containers piling up” in your business

Those containers stuck at sea represented more than just logistical headaches; they translated to lost revenue, delayed product launches, and deeply unhappy customers. This same principle applies directly to your business. As we discussed in a previous post post, long customer queues aren’t just an inconvenience – they come with significant costs.

Lost sales

Customers may abandon their purchase or service if the wait is too long. In e-commerce, this might mean an abandoned cart after a frustrating checkout process. In retail, it could mean a customer walking out of the store without buying anything. In service industries, it could result in missed appointments or canceled subscriptions. The longer the wait, the higher the likelihood of losing that customer entirely.

Damaged reputation

Negative waiting experiences erode customer loyalty and fuel negative word-of-mouth. In today’s digital age, those negative experiences are amplified through online reviews and social media, potentially damaging your brand’s reputation and deterring new customers. Think of a restaurant with consistently long wait times – it quickly develops a reputation for poor service.

Inefficient operations

Bottlenecks caused by poor queue management tie up valuable resources, decrease employee productivity, and prevent your team from focusing on revenue-generating, value-added tasks. This could mean staff spending excessive time managing customer complaints instead of providing excellent service, or equipment sitting idle while waiting for input. These inefficiencies translate directly into higher operational costs and reduced profitability.

Don’t let your customers get stuck in port

The lessons from the global supply chain disruptions are clear: understanding and proactively managing the dynamics of flow and capacity are crucial for operational efficiency and customer satisfaction.

Just as businesses are working to build more resilient supply chains to withstand future shocks, you can build more resilient and customer-centric operations by effectively managing your queues.

Want to dive deeper into why long waits hurt your business? Read our article on the hidden cost of waiting times.